Our technical team has the core technology and experience in lean production, the technical chief engineer and the team have more than 15 years in the development and design of planetary reducer, which enables us to provide outstanding technical support and solutions to help customers achieve efficient production processes and continuous improvement.

Innovative R&D concept

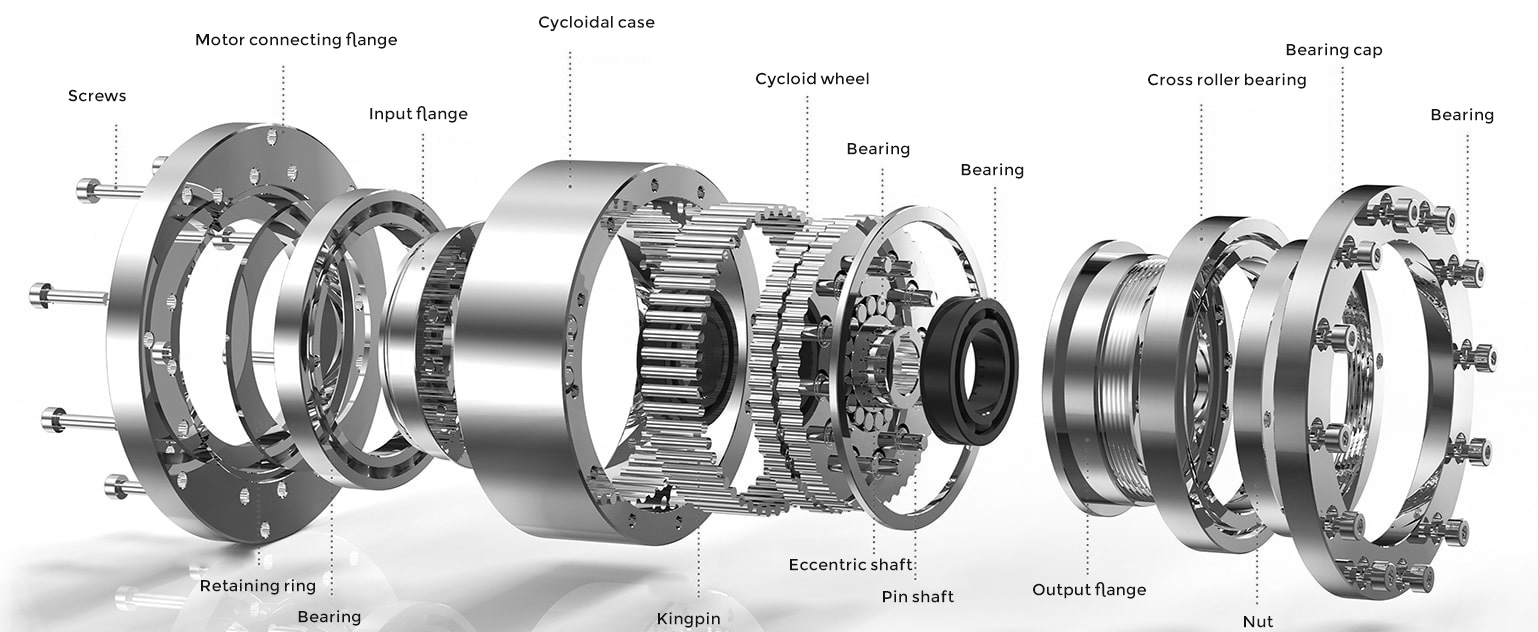

MAKIKAWA innovates and develops high, precise and sharp precision reducer products. The new generation of planetary reducer and harmonic reducer developed by Makikawa has the characteristics of high precision, high torsional stiffness, high reliability, low noise, long life, maintenance-free, etc.

Cooperative optimization of production

As an experienced team, we understand the core principles and tools of lean manufacturing, such as process optimization, value stream analysis, standardization work, continuous improvement, etc. We are able to work with our customers to effectively reduce waste and increase capacity and quality on the production line.

en

en русский

русский Deutsch

Deutsch 日本語

日本語 Español

Español 简体中文

简体中文