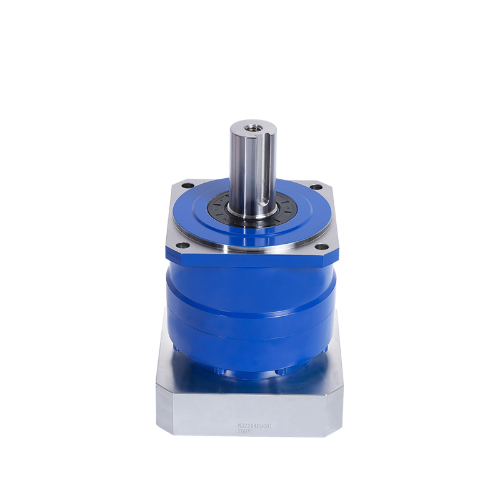

Door Driving Precision Planetary Reducer

Cat:MK series planetary reducer

Industry-product lineupApplicable to: Door drive (planetary, coaxial shaft)MKB Precision Planetary Reducer is a cutting-edge mechanical device designe...

See DetailsIn the realm of engineering marvels, high precision planetary gear reducers stand tall as the unsung heroes behind seamless machinery operations. From robotic arms in factories to the gears of space exploration vehicles, these compact wonders are pivotal in ensuring efficiency and reliability.

Imagine a world where every intricate movement is orchestrated with flawless precision. This is made possible by the silent champions known as high precision planetary gear reducers. These compact devices may seem small in stature but wield immense power in the grand scheme of mechanical operations. In this article, we will explore their inner workings, applications across industries, and the transformative impact they have on technology.

At the heart of every high precision planetary gear reducer lies a complex yet elegant system of gears working in perfect harmony. Unlike traditional gear systems, planetary gear reducers feature a central gear (sun gear) surrounded by smaller gears (planet gears) that rotate around it within an outer ring (annulus). This unique configuration not only enhances torque distribution but also minimizes backlash, ensuring smooth and precise movement crucial for high-precision applications.

The versatility of high precision planetary gear reducers extends across a wide spectrum of industries. In manufacturing, these reducers play a crucial role in robotic automation, where accuracy and reliability are paramount. They also find application in aerospace, where they support the intricate movements of satellite antennas and solar arrays in harsh space environments. Moreover, in medical devices and surgical robots, these gear reducers enable precise control during delicate procedures, safeguarding both patients and practitioners.

As technology advances, so too do high precision planetary gear reducers. The demand for smaller, lighter, and more efficient gear systems continues to drive innovation in materials and manufacturing techniques. Carbon fiber composites and advanced lubricants are revolutionizing gear durability and efficiency, paving the way for even more compact and powerful solutions. Experts predict a future where these reducers will be integral to the next generation of autonomous vehicles, industrial drones, and wearable robotic exoskeletons.

High precision planetary gear reducers are the unsung heroes powering the machinery of progress across various industries. Their ability to deliver precise torque, minimize space requirements, and enhance operational efficiency makes them indispensable in today's technology-driven world. Whether in manufacturing, aerospace, or healthcare, these compact powerhouses continue to push the boundaries of what's possible. As we look to the future, one thing remains certain – the evolution of high precision planetary gear reducers will shape the landscape of innovation for years to come.