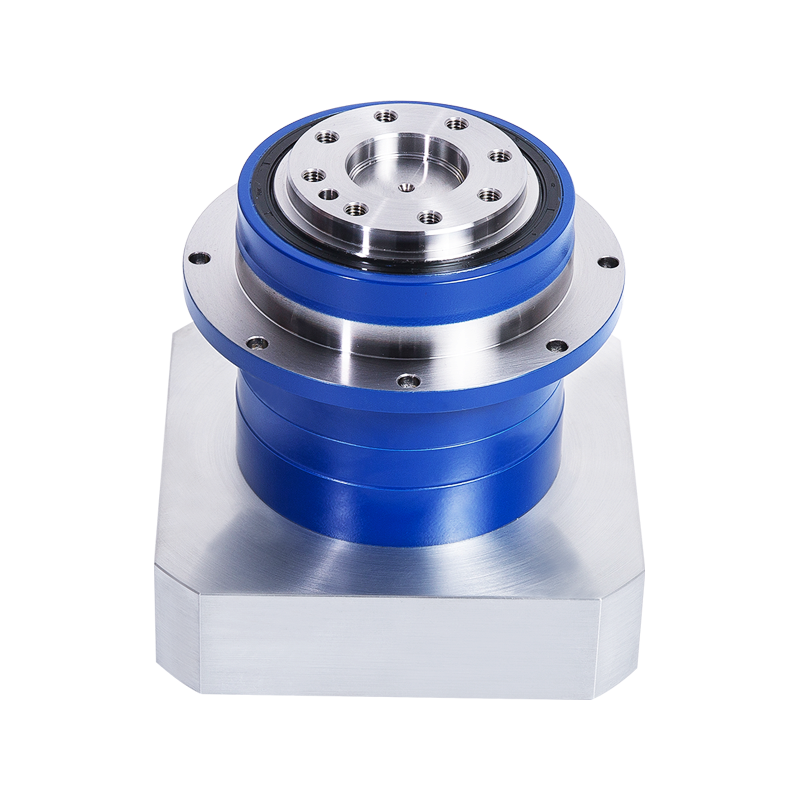

Servo Motor MKT Precision Planetary Reducer

Cat:MK series planetary reducer

Meet the needs of customers with high precision requirements for semiconductor devices, automation equipment, machine tools, etc.Applicable to: Door d...

See DetailsPlanetary gearboxes, also known as epicyclic gear systems, represent one of the most efficient and compact power transmission mechanisms available to engineers. Characterized by their unique configuration of gears, these systems derive their name from the visual resemblance to a planetary solar system, with central "sun" gears surrounded by orbiting "planet" gears all contained within an outer "ring" gear.

The sun gear (center) drives multiple planet gears which rotate within the ring gear (outer circle). The planet gears are mounted on a carrier that can either rotate or be held stationary.

Understanding the purpose of planetary gearboxes begins with examining their fundamental components:

The central gear that receives input power from the motor or engine. It engages with the surrounding planet gears, transferring rotational energy to them.

Typically three to six gears that mesh with both the sun gear and the ring gear. These gears are mounted on a carrier and rotate around the sun gear while also spinning on their own axes.

The outermost gear with internal teeth that meshes with the planet gears. Depending on the configuration, the ring gear can be held stationary, rotate, or serve as the output element.

The structure that holds the planet gears in position and maintains their orientation relative to each other. The carrier can serve as either input or output depending on the desired gear ratio.

The functionality of planetary gear systems arises from the kinematic relationships between their components. Depending on which component is fixed, which serves as input, and which as output, different gear ratios and rotational directions can be achieved.

The fundamental equation governing planetary gear systems is: (R + S) × ωc = R × ωr + S × ωs

Where R is ring gear teeth, S is sun gear teeth, and ω represents the angular velocities of the carrier (c), ring (r), and sun (s).

Planetary gear systems are employed across industries due to their unique combination of characteristics:

Planetary gearboxes distribute load across multiple planet gears, enabling them to transmit significantly more torque relative to their size compared to parallel-axis gear systems.

The concentric arrangement of components results in a smaller footprint, making planetary systems ideal for space-constrained applications where high torque transmission is required.

With power distributed across multiple gear meshes, planetary systems achieve efficiencies of 97-99% per stage, minimizing energy losses in power transmission.

By fixing different components (sun, carrier, or ring), engineers can achieve different gear ratios, torque multiplication factors, and rotational directions from the same basic gearset.

The symmetrical arrangement of planet gears creates balanced forces that cancel out vibrations, resulting in smoother operation compared to other gear types.

| Gearbox Type | Torque Density | Efficiency | Compactness | Typical Applications |

| Planetary | Very High | 97-99% | Excellent | Robotics, automotive, aerospace |

| Spur | Moderate | 95-99% | Good | Conveyors, simple machinery |

| Helical | High | 95-98% | Moderate | Pumps, compressors, industrial |

| Bevel | Moderate | 95-98% | Good | Right-angle drives, differentials |

| Worm | Low-Moderate | 50-90% | Good | Lifting equipment, high ratio |

Planetary gearsets form the foundation of automatic transmissions, providing multiple gear ratios, smooth shifting, and compact packaging within vehicle drivetrains.

Robotic joints benefit from planetary gearboxes due to their high torque-to-weight ratio, precision, and low backlash characteristics essential for accurate positioning.

Used in aircraft actuators, engine accessories, and helicopter rotor systems where reliability, compactness, and high power density are critical requirements.

Planetary stages in wind turbine gearboxes efficiently transmit high torque from rotor blades to generators while withstanding variable loading conditions.

Precision planetary gearboxes enable smooth, accurate motion control in imaging systems, surgical robots, and diagnostic machinery requiring low noise and vibration.

EV powertrains utilize planetary gear systems to provide torque multiplication and speed reduction in a compact form factor within electric drive units.

Engineers have developed multiple planetary configurations to meet specific application requirements:

The basic configuration with one sun gear, planet gears, ring gear, and carrier. Provides a single reduction ratio typically between 3:1 and 12:1.

Multiple planetary stages connected in series to achieve higher reduction ratios without excessive component size. Common in industrial reducers requiring ratios up to 100:1.

Configured with two inputs and one output (or vice versa) to provide speed/torque summing capabilities. Used in hybrid vehicle transmissions and power-split devices.

While similar, solar arrangements feature planet gears that do not rotate on their axes, instead orbiting while maintaining fixed orientation relative to the carrier.

The demanding operating conditions of planetary gearboxes require careful material selection:

Case-hardened alloy steels (e.g., AISI 8620, 9310) provide excellent strength and durability. High-performance applications may use nitrided steels or specialized alloys.

Carburizing, nitriding, and specialized coatings enhance surface hardness, improve wear resistance, and reduce friction between meshing gear teeth.

Precision planetary systems employ splash lubrication, forced oil circulation, or grease lubrication depending on operating speed, temperature, and duty cycle requirements.

Proper maintenance ensures longevity and reliable performance of planetary gear systems:

Regular oil analysis and scheduled changes prevent wear from contamination. Proper viscosity selection based on operating temperature is critical.

Periodic vibration analysis detects developing issues like bearing wear, gear tooth damage, or misalignment before catastrophic failure occurs.

Monitoring operating temperatures prevents overheating which can degrade lubricants and accelerate component wear.

Planetary gearbox technology continues to evolve to meet emerging engineering challenges:

Increasing integration of planetary reducers with electric motors creates compact mechatronic units with optimized performance characteristics.

Development of composite materials and specialized alloys enables lighter, stronger gear systems for aerospace and electric vehicle applications.

3D printing technologies allow production of complex gear geometries and lightweight structures previously impossible with traditional manufacturing methods.

Planetary gear systems serve a critical purpose in modern machinery by providing an optimal solution for applications requiring high torque density, compact dimensions, and operational efficiency. Their unique configuration enables engineers to transmit substantial power through a small package while maintaining excellent durability and smooth operation. As technology advances, planetary gearboxes continue to evolve, finding new applications in robotics, renewable energy, electric transportation, and beyond.