In the world of machinery and motion, raw power is often not enough. An engine or electric motor might spin incredibly fast, but what if you need immense force to turn a heavy load or precise, slow movement for a specific task? This is where the unsung hero of mechanics comes into play: the reduction gearbox. This fundamental device is crucial in everything from the car you drive to the elevator you take and the conveyor belts in factories. Understanding how it works and its benefits is key for anyone involved in engineering, manufacturing, or simply curious about the mechanics of everyday life.

The Core Principle: Trading Speed for Torque

At its heart, a speed reducer (another common name for a reduction gearbox) operates on a simple but powerful principle of mechanical advantage. Its primary function is to reduce the input speed from a motor (measured in RPM, or Revolutions Per Minute) while simultaneously increasing the output torque (the rotational force).

Think of it like the gears on a bicycle. When you shift into a low gear to pedal up a steep hill, you are making it easier to turn the wheels by spinning the pedals much faster. The bicycle’s gear system is a simple form of speed reduction—your legs move quickly with less force, and the rear wheel moves slowly but with enough torque to climb the incline. A reduction gearbox does the exact same thing for machinery.

This trade-off is defined by a key value known as the gear ratio. If a gearbox has a 10:1 ratio, it means the input shaft must rotate ten times for the output shaft to rotate once. This single output rotation will have roughly ten times the torque of the input (minus a small percentage lost to friction), making it vastly more powerful.

How Does a Reduction Gearbox Achieve This?

The magic happens through an arrangement of gears of different sizes. The most common configurations include:

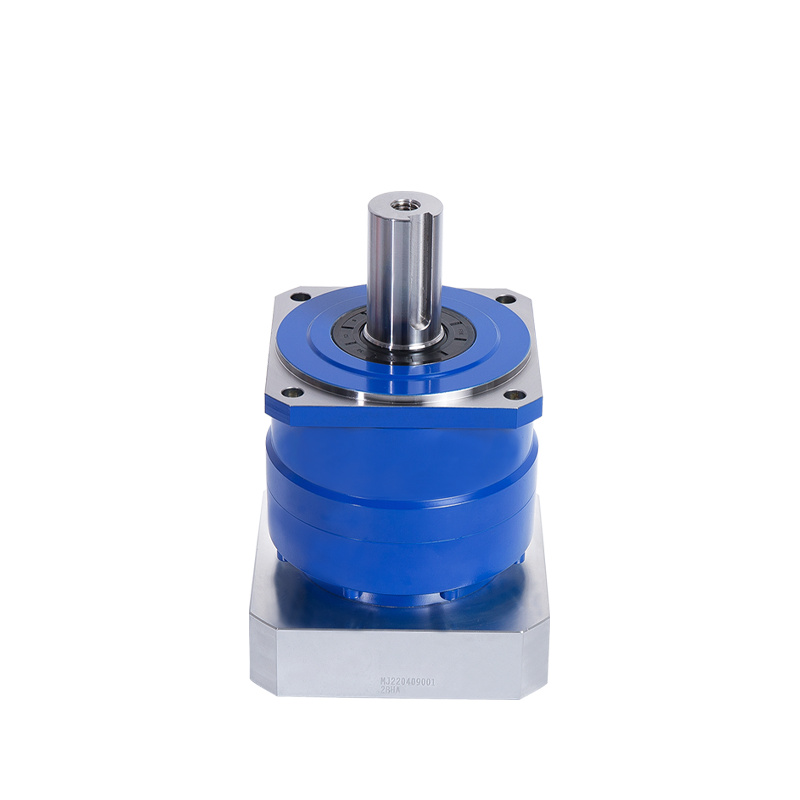

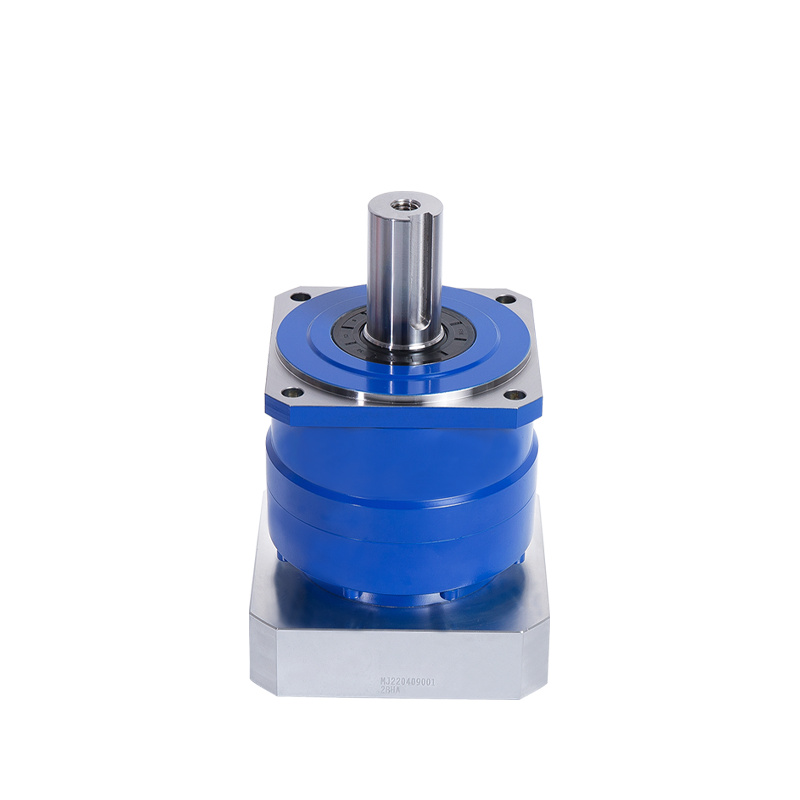

- Planetary Gearboxes (Epicyclic Gearing): Named for their sun-and-planet-like structure, these are known for their high efficiency, compact size, and ability to handle high torque loads. They are common in automotive transmissions, industrial robots, and anywhere space is limited but power demands are high.

- Worm Gear Reducers: These use a threaded screw (the worm) to mesh with a gear (the worm wheel). This setup offers very high reduction ratios in a single stage and a distinct advantage: the worm can easily turn the gear, but the gear cannot turn the worm. This provides a built-in locking mechanism or self-locking feature, which is perfect for applications like conveyor belts or hoists where holding a load in place is critical to safety.

- Helical Gear Reducers: These use gears with angled teeth that engage more smoothly than straight-cut (spur) gears. This results in quieter operation, higher efficiency, and the ability to transmit greater loads, making them a popular choice for heavy-duty industrial applications.

- Bevel Gear Reducers: These are designed to change the direction of power transmission, typically by 90 degrees, while also reducing speed and increasing torque. They are found in hand drills, marine propellers, and vehicle differentials.

Each type has its own advantages in terms of efficiency, noise level, physical size, and cost, making the selection process crucial for optimal performance.

Key Benefits and Why They Are Non-Negotiable

- Torque Multiplication: This is the primary reason for their use. A small, fast-spinning, and relatively inexpensive motor can be paired with a gearbox to generate the massive force needed to move industrial equipment, construction machinery, or agricultural implements.

- Speed Control: Many processes require slow, controlled, and precise movement. A reduction gearbox provides this controlled speed inherently and reliably, without the need for complex electronic motor controllers that can be less robust and more expensive.

- Load Inertia Matching: From a motor’s perspective, a large, heavy load is difficult to get moving and stop (it has high inertia). A gearbox reduces the “reflected inertia” of the load back to the motor, making it easier for the motor to control the load smoothly and preventing damage from sudden jolts or stops.

- Physical Size Optimization: High-torque, low-speed motors are typically large, heavy, and expensive. A system combining a compact, high-speed motor with a reduction gearbox is often a much more space-efficient and cost-effective solution.

Common Applications and Uses

You are surrounded by reduction gearboxes. They are integral components in:

- Industrial Machinery: Conveyor systems, mixing machines, crushers, and extruders all rely on gearboxes to provide the slow, powerful force needed for processing materials.

- Automotive Industry: In electric vehicles and traditional cars, gear reducers are used in the transmission and differential to transfer power from the engine to the wheels at the right speed and torque.

- Robotics and Automation: Robotic arms require precise, powerful, and compact movement, making planetary and harmonic drive gearboxes essential for their operation.

- Consumer Appliances: The agitator in your washing machine and the lift mechanism in a stand mixer use a gear reduction system to perform their tasks effectively.

- Renewable Energy: The massive gearbox in a wind turbine nacelle converts the slow rotation of the blades into the high-speed rotation needed by the generator to produce electricity efficiently.

Selecting the Right Gear Reduction System

Choosing a gearbox isn’t just about picking a ratio. A proper gearbox selection guide would advise you to consider:

- Required Output Torque and Speed: What is the load, and how fast does it need to move?

- Duty Cycle: Will it run continuously or intermittently? Shock loads can significantly impact the design.

- Mounting Orientation and Space Constraints: How and where will it be installed?

- Environmental Conditions: Does it need to be sealed against dust or moisture (e.g., washdown duty in food processing)?

- Backlash Requirements: How much mechanical free play between gears is acceptable? Precision automation often demands very low backlash.

Proper gearbox maintenance, including the use of the correct lubricant and monitoring for wear, is also critical for long service life and preventing unexpected downtime.

In conclusion, the reduction gearbox is a masterpiece of fundamental mechanical engineering. It solves a universal problem in power transmission by providing a robust, efficient, and reliable method to get the right combination of speed and force for virtually any task. By understanding its function and benefits, engineers and technicians can make informed decisions that keep the wheels of industry—and everyday life—turning smoothly.