In the world of industrial automation, the smooth, reliable, and efficient movement of materials is paramount. At the heart of countless conveyor belts, palletizers, and automated guided vehicles (AGVs) lies a critical component often hidden from view: the planetary gear reducers. Far from being a simple accessory, this precision gearbox is a key engineering solution that makes modern material handling possible.

Understanding the Core Problem: Why a Reducer is Needed

Most electric motors used in industry operate at high speeds but produce relatively low torque—the rotational force that does the actual work of moving a load. A conveyor belt laden with heavy packages or a lifting mechanism hoisting a pallet requires immense torque to start moving and to maintain motion, but it does not require the motor’s high rotational speed.

This is where a speed reducer, or gearbox, comes in. Its primary function is to act as a torque multiplier. It takes the high-speed, low-torque input from the motor and converts it into a low-speed, high-torque output perfectly suited for driving the heavy, often slow-moving loads found in material handling.

What is a Planetary Reducer?

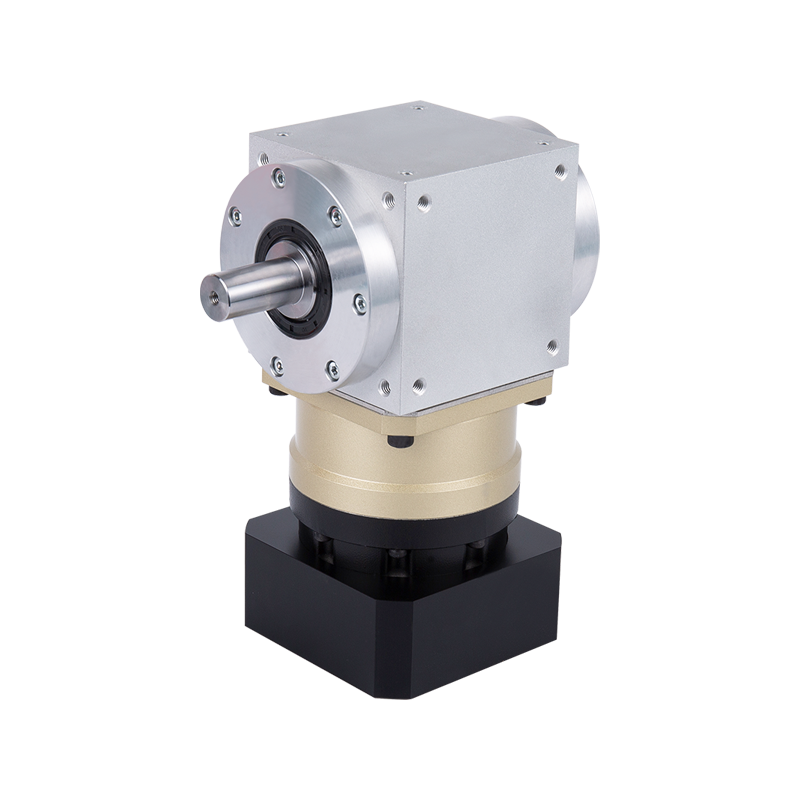

A planetary reducer, also known as an epicyclic gearbox, gets its name from its gear arrangement, which resembles a planetary solar system. It consists of three main components:

Sun Gear: The central, input gear driven directly by the motor.

Planet Gears: Multiple gears (typically 3 or more) that orbit around the sun gear. These are held together by a planet carrier.

Ring Gear (or Annulus Gear): An outer gear with internal teeth that meshes with the planet gears.

In a common configuration, the motor drives the sun gear. The sun gear spins the planet gears, which roll along the inside of the stationary ring gear. This rotation causes the planet carrier, which is connected to the output shaft, to turn. This unique design is the source of its remarkable performance characteristics.

Key Advantages of Planetary Reducers for Material Handling

While other types of reducers exist, planetary designs offer a compelling set of benefits that make them exceptionally well-suited for the rigorous demands of conveyor and material handling systems.

1. High Torque Density and Compact Size

The planetary design distributes the load across multiple planet gears in contact with both the sun and ring gears simultaneously. This load-sharing capability allows a planetary reducer to transmit significantly more torque in a smaller, more compact package compared to other reducer types of equivalent size. This is a critical advantage in space-constrained equipment like AGVs or complex conveyor junctions.

2. Exceptional Efficiency and Low Backlash

With their multiple, symmetrically arranged contact points, planetary reducers achieve very high power transmission efficiency, often exceeding 97% per stage. This means less wasted energy, lower operating costs, and reduced heat generation. Furthermore, the symmetrical force distribution minimizes backlash—the slight amount of “play” or lost motion between gear teeth. Low backlash is crucial for precise positioning and smooth starts and stops, preventing jerky motion that can damage products.

3. High Durability and Rigidity

The 360-degree load distribution within the ring gear creates an extremely robust and rigid structure. This rigidity allows planetary reducers to handle high radial and axial loads from the conveyor pulleys or wheels, leading to a long service life and exceptional shock load resistance. They are built to withstand the constant start-stop cycles and heavy loads typical in distribution centers and manufacturing plants.

4. Coaxial Input and Output Shafts

A distinctive feature of the planetary design is that the input and output shafts are in-line, or coaxial. This creates a very compact and straightforward driveline layout, simplifying the mechanical design and integration into motorized rollers or direct-drive systems.

Practical Applications in Conveyor and Material Handling Systems

The theoretical advantages of planetary reducers translate directly into real-world performance across a wide range of equipment.

1. Heavy-Duty Belt and Roller Conveyors

In mining, bulk handling, or airport baggage systems, conveyors must move thousands of tons of material daily. The high torque output and durability of planetary reducers are essential for driving the head pulleys of these massive systems, ensuring reliable operation under extreme loads and in harsh environments.

2. Precision Indexing and Sorting Systems

In modern e-commerce fulfillment centers, packages must be accurately diverted and sorted at high speeds. The low backlash and high torsional stiffness of planetary reducers enable the precise control needed for these applications. They ensure that a sorter arm or a pop-up diverter moves to the exact position required, every time, without overshoot or delay.

3. Motorized Roller Conveyors

Planetary reducers are the core of many motorized rollers (or “MDRs”). Their compact size allows them to fit neatly inside the roller tube itself, creating a clean, self-contained drive unit. This “direct-drive” approach eliminates the need for external chains, belts, and sprockets, reducing maintenance, noise, and safety hazards.

4. Automated Guided Vehicles (AGVs) and Mobile Robots

The high torque density and efficiency of planetary reducers are invaluable for the drive wheels of AGVs. A compact, powerful reducer allows the vehicle to carry heavier payloads, climb gradients, and operate for longer periods on a single battery charge. Their robustness also ensures they can handle the repeated acceleration and deceleration of a mobile robot’s work cycle.

5. Palletizers and Unit Load Formers

These machines stack products onto pallets, a process that involves lifting heavy weights with precision. Planetary reducers provide the smooth, powerful, and controlled motion necessary for the lift and extension mechanisms, ensuring stable and secure pallet loads without product damage.

Important Selection and Integration Considerations

Choosing the right planetary reducer is not a one-size-fits-all process. Engineers must consider several factors:

Required Torque and Speed: Calculating the exact torque needed to overcome friction, accelerate the load, and account for any incline is the first step.

Service Factor: The reducer is often selected with a service factor (e.g., 1.5 or higher) to provide a safety margin for unexpected shock loads or varying conditions.

Mounting Configuration: Planetary reducers can be foot-mounted, flange-mounted, or integrated directly into the motor (as a planetary gearmotor).

Lubrication and Sealing: The operating environment dictates the need for specific lubricants and sealing solutions to keep contaminants out and ensure long-term reliability.

Conclusion: An Unsung Hero of Industrial Flow

Planetary reducers are not merely components; they are engineered solutions that directly enable the efficiency, reliability, and precision of modern material handling. By offering an unmatched combination of high torque, compact size, durability, and control, they solve the fundamental challenge of converting motor power into usable work. In an era defined by the demand for faster and more automated logistics, the planetary reducer remains an unsung hero, quietly and reliably driving the flow of commerce in facilities around the world.

en

en русский

русский Deutsch

Deutsch 日本語

日本語 Español

Español 简体中文

简体中文